Cotton factory in Bergamo - zeroCO2 XL

Provincia di Bergamo

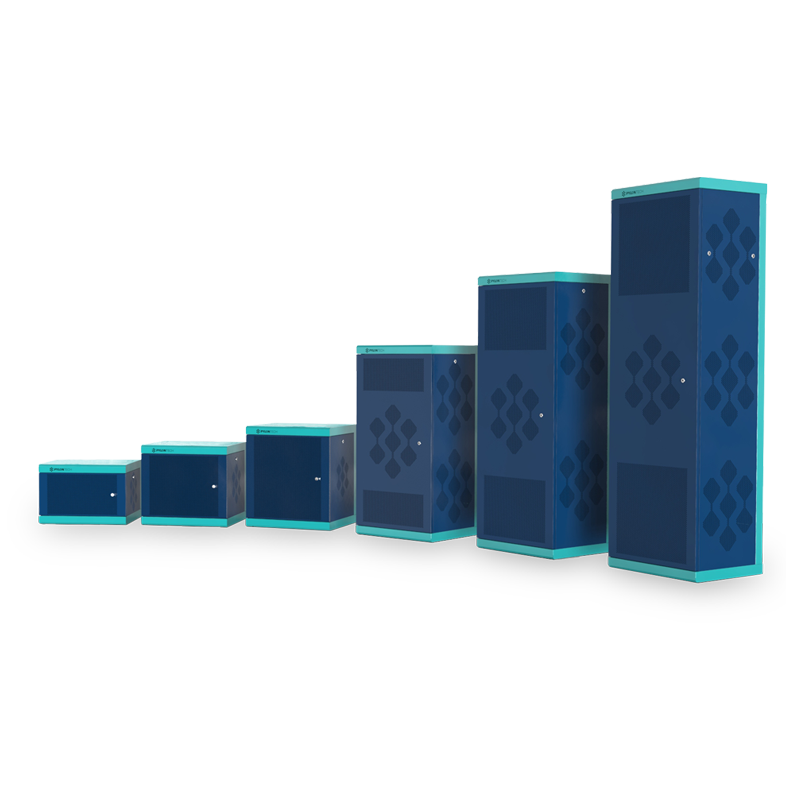

Installed products:

> Rack Cabinet

Storage 325 kWh | Power 120 kW

In the middle of Lombardy, an ancient cotton mill with over half a century of history has decided to look to the future by choosing innovative solutions to optimise its energy consumption. This analysis highlights how this Bergamo cotton mill has adopted an energy storage system to maximise self-consumption and reduce its operating costs.

Features of the PV Plant

Pannels Power: 1 MWp total

Energy Storage Capacity

Storage: 3 cabinets ZeroCO2 XL BESS

Batteries: 23 units H32148 per cabinet

Total Storage: 327,06 kWh

Client Company

With more than 50 years of experience, this Lombard cotton mill specializes in a wide range of textile processes: from fabric preparation and bleaching to dyeing, ennobling, printing, quilting, cutting, and making up, and even warehouse management of finished products. The company is known for its numerous collaborations with nonprofit associations and prominent figures, and is constantly striving to improve and develop its activities.

Demand and Functionality of Storage

The installation of the zeroCO2 XL system aims to manage the high electricity consumption of the cotton mill, which operates on three shifts. The storage system, used mainly during the evening and night hours, allows for the storage of excess energy produced during the day by the PV system. This makes it possible to offset the company's power consumption when the PV system is not sufficient, ensuring a constant supply of 120 kW until the set discharge capacity is reached.

Benefits for the company

Thanks to the installation of the storage system, the company now benefits from four hours of autonomy at night. This translates into significant savings in energy costs and also helps to reduce the company's carbon footprint and promote more sustainable operations.

This Bergamo cotton mill is a prime example of how ancient manufacturing traditions can be perfectly integrated with technological innovations. By adopting the ZeroCO2 XL storage system, the company has not only reduced its energy costs, but has also taken a step in the direction of a greener, more sustainable future.

Installed products

More references

zeroCO2 XL indoor at Biotechnology Research Laboratory

Storage 250 kWh | Power 120 kW

zeroCO2 XL indoor for Production and processing of paper for hygienic and sanitary use,

Storage 120 kWh | Power 60 kW

zeroCO2 XL indoor Consorzio Industriale CIPNES Sardegna

Storage 120 kWh | Power 60 kW